04

2025-03

Application fields of peristaltic pumps

Chemical industry; Mining and metallurgy industry; Paper industry; Paint and coating industry; Food industry; Ceramics industry; Petroleum industry; Water treatment industry; Pharmaceutical industry; Medical device industry;

2025-03-04

04

2025-03

The peristaltic pump filling machine is easy to maintain.

The peristaltic filling machine consists of a filling system composed of a main drive system, a bottle feeding system, a pump head assembly, and a filling distribution assembly;

2025-03-04

04

2025-03

Limitations of peristaltic pumps

1. Pressure limitations: Using flexible pipes will limit the pressure they can withstand. 2. The pump produces a pulsating flow while operating.

2025-03-04

04

2025-03

Maintenance is the daily work of the filling machine

Any enterprise purchasing filling machine equipment hopes that the equipment can play a good role in production and improve production efficiency.

2025-03-04

04

2025-03

Daily maintenance of peristaltic pumps

During daily use, replace the tube after prolonged use to prevent silicone tube breakage. If liquid leaks from the tube into the pump head roller, and corrosive liquid enters the roller gap

2025-03-04

04

2025-03

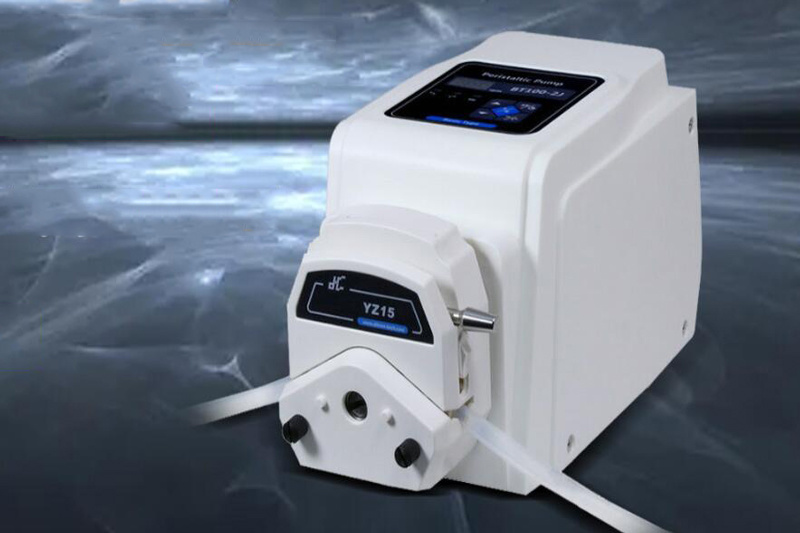

Precautions for Peristaltic Pump Selection

As a peristaltic pump tube, it needs to be somewhat elastic, meaning it can quickly recover its shape after being radially compressed. It needs to be wear-resistant, able to withstand pressure, leak-proof (good airtightness), have low adsorption

2025-03-04

04

2025-03

Granular paste filling machine

Suitable for pharmaceuticals, daily chemicals, food, pesticides, and special industries, it is an ideal filling equipment for granular and paste-like viscous fluids. This machine is a semi-automatic piston filler that can fill granular and paste-like fluid materials.

2025-03-04

04

2025-03

The difference between peristaltic pumps and chemical pumps

It is understood that peristaltic pumps are a rapidly developing technology globally. Typically, chemical corrosives erode the valves, seals, rotors, and moving parts of diaphragm pumps and single-screw pumps, leading to pump damage and production interruptions.

2025-03-04

04

2025-03

Diaphragm pump applications and suitable locations

Pneumatic diaphragm pumps have prominent characteristics. Since their advent, they have gradually penetrated the markets of other pumps and occupied a certain market share. They are irreplaceable in environmental protection, wastewater treatment, construction, sewage discharge, and fine chemical industries.

2025-03-04

04

2025-03

Superiority of peristaltic pumps

1. Pollution-free: The fluid only contacts the pump tube, not the pump body; 2. High precision: High repeatability and stability precision;

2025-03-04