Environmental Protection and Wastewater Treatment

Published time:

2025-03-31

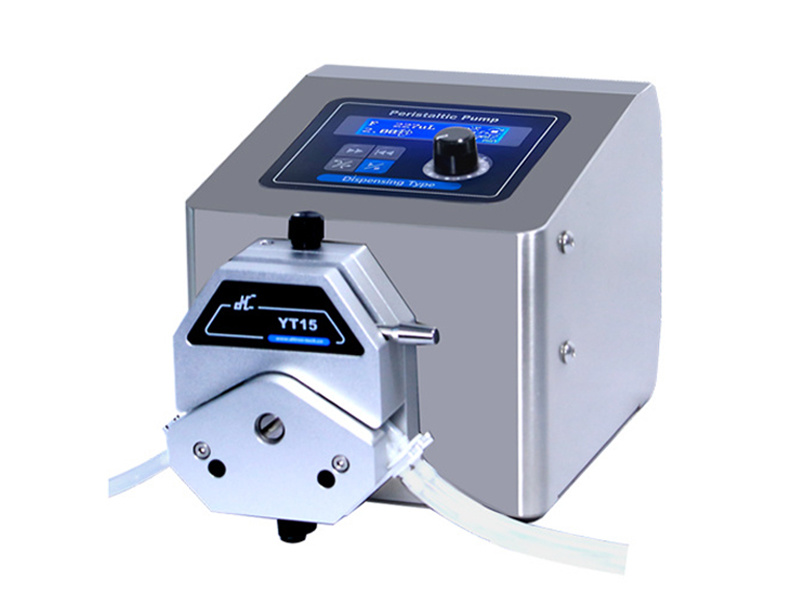

The core advantages of peristaltic pumps in the field of environmental water treatment are their resistance to clogging, strong corrosion resistance, high metering accuracy, and low maintenance costs. They are widely applicable throughout the entire process—including municipal wastewater treatment, industrial effluent treatment, pure water production, and water quality monitoring—and excel particularly in conveying fluids containing impurities, corrosive chemicals, or requiring precise dosing. Below are specific application scenarios, key advantages, and selection guidelines:

I. Core Application Scenarios

- Precise dosing of pharmaceutical agents

- Flocculant / Coagulant Dosage For viscous chemicals or those containing trace particles—such as PAC (polyaluminum chloride) and PAM (polyacrylamide)—peristaltic pumps can stably control the dosage, thereby preventing chemical waste and ensuring consistent treatment performance.

- Alkaline-acid neutralization agent dosing For substances such as sulfuric acid and sodium hydroxide solutions, selecting corrosion-resistant pump tubing can prevent corrosion of the pump body and enable precise adjustment of the water’s pH value.

- Disinfectant dosing Such as sodium hypochlorite, chlorine dioxide, and hydrogen peroxide, these substances carry no risk of leakage, ensuring the safety of operators while also allowing for precise control of disinfection concentrations.

- Nitrogen and phosphorus removal chemical dosing Such as urea and phosphates, precisely supplying the requirements suited to biochemical treatment processes.

- Wastewater/ Sewage Conveyance and Treatment

- Wastewater Transport Containing Particles For substances such as industrial wastewater, sludge return liquid, and leachate from landfills, peristaltic pumps—lacking impellers, valves, and other components prone to clogging—will not become blocked or suffer wear due to solid particles.

- Membrane treatment system accessories In ultrafiltration and reverse osmosis (RO) processes, stable flow rates for conveying raw water, backwash water, or cleaning agents can protect membrane components and prevent shock damage.

- Sludge dewatering stage Delivers sludge conditioning agents or assists in feeding sludge to filter presses, suitable for high-viscosity sludge media.

- Pure Water / Reclaimed Water Recycling Process

- Chemical dosing for reverse osmosis systems Such as scale inhibitors and reducing agents, precise metering can prevent membrane fouling and extend membrane lifespan.

- Reclaimed water reuse and conveyance Deliver the treated reclaimed water to the reuse point without any risk of secondary pollution.

- Water Quality Monitoring and Sampling

- Online monitoring equipment配套 Continuously delivers water samples, color-developing agents, and standard solutions to the monitoring instrument, enabling real-time detection of indicators such as COD, ammonia nitrogen, and heavy metals.

- Automatic water sampling Collect wastewater and surface water samples at scheduled times and in fixed quantities, leaving no sample residue to ensure the accuracy of test data.

II. Core Advantages in the Field of Eco-Friendly Water Treatment

- Strong anti-blocking capability, suitable for complex media.

With no valves, seals, or other easily clogged components, this pump can reliably convey sewage or chemicals containing suspended solids, particles, and fibers, thereby addressing the common issues of clogging and frequent maintenance associated with conventional pumps (centrifugal pumps and diaphragm pumps).

2. Excellent corrosion resistance, reducing equipment wear and tear.

The fluid comes into contact only with the pump tubing; the pump body remains completely isolated from corrosive media. By simply replacing the pump tubing with corrosion-resistant materials such as fluororubber or PTFE, you can safely convey chemicals like acids, bases, and oxidizers—without having to invest in an expensive corrosion-resistant pump body.

3. Accurate measurement, controllable chemical dosing.

Keywords:

Previous

Previous:

Next:

Product recommendation