Medical

Published time:

2025-03-31

The core advantages of peristaltic pumps in the medical field are sterile delivery, ultra-precise dosing, low shear force, and zero cross-contamination. They are widely used in clinical treatments, laboratory testing, pharmaceutical R&D, and other applications, serving as critical equipment for ensuring the safety and accuracy of fluid delivery in medical settings. Below are specific application scenarios, key advantages, and selection guidelines:

I. Core Application Scenarios

- Precise Infusion / Administration It is used for drug infusion in ICUs, operating rooms, and general wards, including antibiotics, chemotherapy drugs, and nutritional solutions (parenteral nutrition), among others. It allows precise control of the infusion rate—from microliters per hour to milliliters per hour—eliminating errors associated with manual adjustment of drip rates and reducing medication-related risks.

- Hemodialysis / Peritoneal Dialysis Support It conveys dialysate, replacement fluid, or fluids for assisting blood circuit circulation. Its low-shear design helps prevent red blood cell damage, ensuring effective dialysis and patient safety.

- Wound Irrigation and Negative-Pressure Drainage It delivers physiological saline, antibacterial irrigation solutions, or drains wound exudates; its sterile delivery characteristics help reduce the risk of wound infection.

- Insulin infusion (small, portable) Combined with a miniature peristaltic pump, this device functions as an insulin pump, enabling continuous, low-dose infusion around the clock to precisely control blood glucose levels.

- Sample Pre-processing It transports biological samples such as blood, urine, and cerebrospinal fluid, or transfers diluents and reagents; its non-cross-contamination feature ensures the accuracy of test results.

- Analyzer accessories Deliver samples, reagents, and buffers to equipment such as biochemical analyzers, immunoassay analyzers, and PCR instruments; a stable flow rate ensures the repeatability of instrument measurements.

- Cell Culture and Biological Experiments For the delivery of culture media, cell suspensions, trypsin, and other substances, low-shear force ensures the preservation of cell viability and is well-suited to meet the laboratory’s needs for small-volume, high-precision fluid handling.

- Medical nebulizer Some nebulization devices use miniature peristaltic pumps to deliver medication, precisely controlling the dosage and enhancing the effectiveness of respiratory disease treatment.

- Vaccine and Biological Product Manufacturing In the vaccine purification and protein drug preparation stages, sensitive biological materials are conveyed while avoiding damage to their active structures; at the same time, GMP-compliant sterile production requirements are met.

II. Core Strengths in the Healthcare Sector

Sterile and safe, compliant with medical certification standards.

Pump tubing that comes into contact with fluids can be selected from: Medical-grade silicone, PTFE Material, compliant with USP Class VI, ISO 10993 Meets medical-grade biocompatibility standards with no release of harmful substances; furthermore, the fluid comes into contact only with the pump tubing, while the pump head remains completely isolated from the material. This design enables sterile delivery via methods such as steam-in-place (SIP) sterilization and gamma-ray sterilization, effectively eliminating any risk of infection.

Highly precise measurement, meeting the needs of micro-dosing.

Flow accuracy can reach ±0.5% to ±1% It supports micro-upgrade and micro-dosing delivery, with flow rates precisely adjustable—from as low as 0.1 mL/h to as high as 100 mL/h—fully meeting the clinical needs for micro-dosing administration and laboratory precision sample addition, thereby avoiding medical risks caused by dosage errors.

Low shear force, protecting sensitive biological materials

The roller-squeezing hose conveying method generates extremely low shear forces, effectively protecting the viability of sensitive biological materials such as blood cells, protein-based drugs, and vaccines. It prevents cell rupture and protein denaturation caused by shear forces, thereby ensuring the efficacy of both therapeutic treatments and experimental studies.

- For different patients or samples, use dedicated pump tubing; simply replacing the pump tubing can completely eliminate cross-contamination, making it particularly suitable for transporting chemotherapy drugs and samples from patients with infectious diseases.

- The pump tubing is easy to disassemble and replace, eliminating the need for complex cleaning procedures, thereby reducing the workload for medical staff and improving work efficiency.

Stable operation, safe handling

Supports intermittent/continuous operation, can run idle without risk of dry-running damage; some medical models are equipped with this feature. Blockage alarm, bubble detection The function immediately stops the machine and triggers an alarm upon detection of pipe blockage or air bubbles, ensuring patient safety.

Keywords:

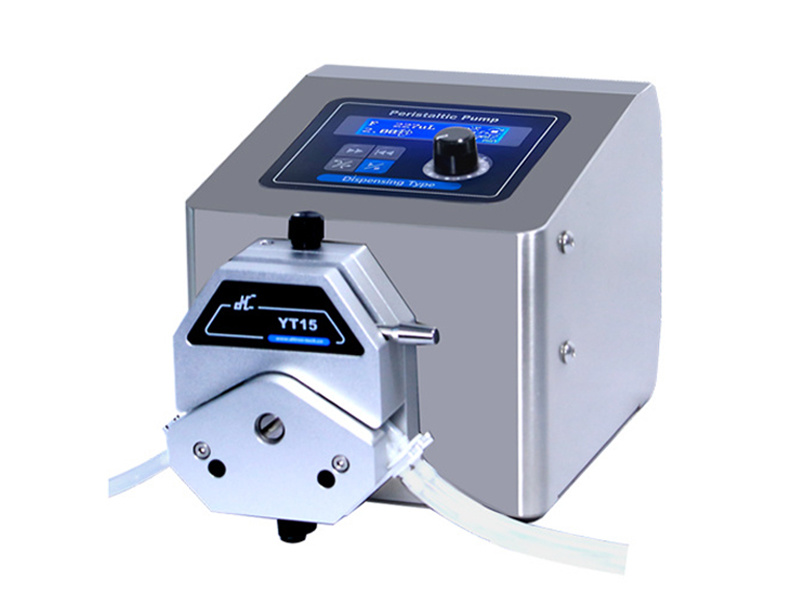

Product recommendation