Printing and Packaging

Published time:

2025-03-31

The core advantages of peristaltic pumps in the printing and packaging industry include precise metering, wide compatibility with various media, convenient cleaning and maintenance, and zero cross-contamination. They can be applied to critical processes such as ink delivery, quantitative dispensing of adhesives, and paint formulation. These pumps are particularly well-suited for handling high-viscosity fluids, fluids containing particles, or fluids that demand high precision in mixing ratios. Below are specific application scenarios, key advantages, and selection guidelines:

I. Core Application Scenarios

- Printing Process: Precise Delivery of Ink and Additives

- Ink Circulation and Refilling It delivers ink in a quantified manner to the ink ducts of offset, flexographic, and gravure printing equipment. A stable ink flow helps prevent issues such as color variations, thread breakage, and plate smearing caused by fluctuations in ink quantity. It is compatible with various types of inks, including solvent-based, water-based, and UV-curable inks.

- Quantitative addition of additives Precisely add diluents, defoamers, and drying agents to the ink, with a control accuracy of up to ±1% in proportion. This ensures stable ink viscosity and drying speed, thereby enhancing the consistency of printed materials.

- Inkjet printing ink supply It delivers high-viscosity ink to digital inkjet printers, and its low-shear design helps protect the pigment particles in the ink, preventing nozzle clogging.

- Packaging process: Adhesive and coating metering and application

- Quantitative coating of adhesive In processes such as film lamination, box sealing, and label application, precisely deliver hot melt adhesives, water-based adhesives, and pressure-sensitive adhesives, control the coating thickness to ensure uniformity, reduce adhesive waste, and prevent packaging from coming unglued or experiencing adhesive overflow.

- Packaging surface coating treatment Apply waterproof coatings, wear-resistant coatings, and anti-counterfeiting coatings to packaging materials such as cardboard boxes and plastic films. A stable coating application rate ensures consistent coating thickness, enhancing both the texture and functionality of the packaging.

- Laminating adhesive conveyance To provide uniform adhesive for the laminating machine, prevent bubbles and wrinkles during lamination, and enhance the adhesion strength of the laminate.

- Post-printing processing: Special-process fluid conveyance

- Gilding paste / Embossed oil delivery It delivers specialized pastes for hot stamping and embossing equipment, precisely controlling the coating amount to ensure clear patterns with strong three-dimensional effects.

- UV Curing Agent Refill Deliver curing agents to UV curing equipment, coordinating with the ink curing speed to enhance post-printing processing efficiency.

- Equipment Cleaning and Waste Liquid Recovery

- The conveying and cleaning fluid (such as solvents or specialized cleaning agents) is used to clean the ink paths and coating rollers of the printing machine. The pump tubing is resistant to corrosion by organic solvents; after cleaning, simply replacing the pump tubing allows for a seamless switch between materials without any cross-contamination.

- Recycle printing waste liquids (such as waste ink and waste adhesive) to prevent leakage and contamination of the workshop environment.

II. Core Advantages in the Printing and Packaging Field

- Accurate measurement, enhancing product consistency.

- Strong media compatibility, suitable for a wide variety of fluids.

- No cross-contamination, easy material change.

- Low shear force, preserving material properties

- Low maintenance costs, simple operation.

Keywords:

Next

Next:

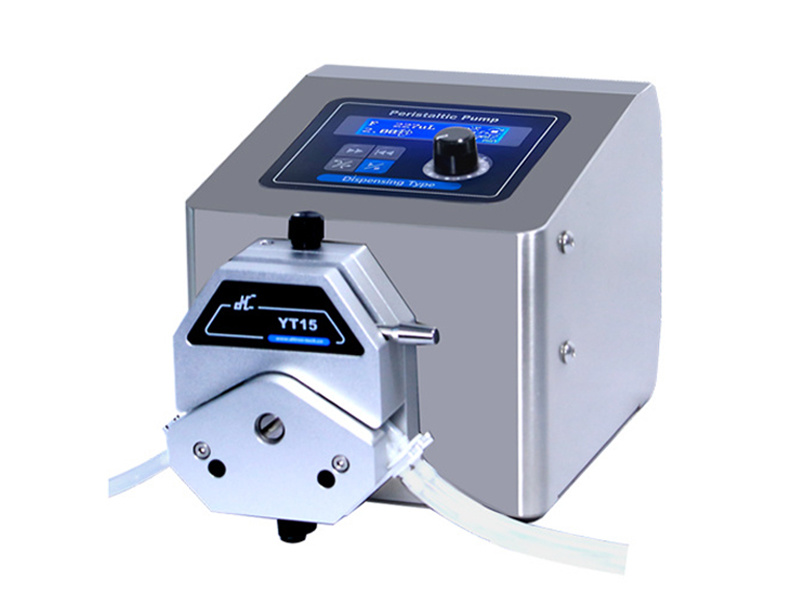

Product recommendation