Biopharmaceutical

Published time:

2025-03-31

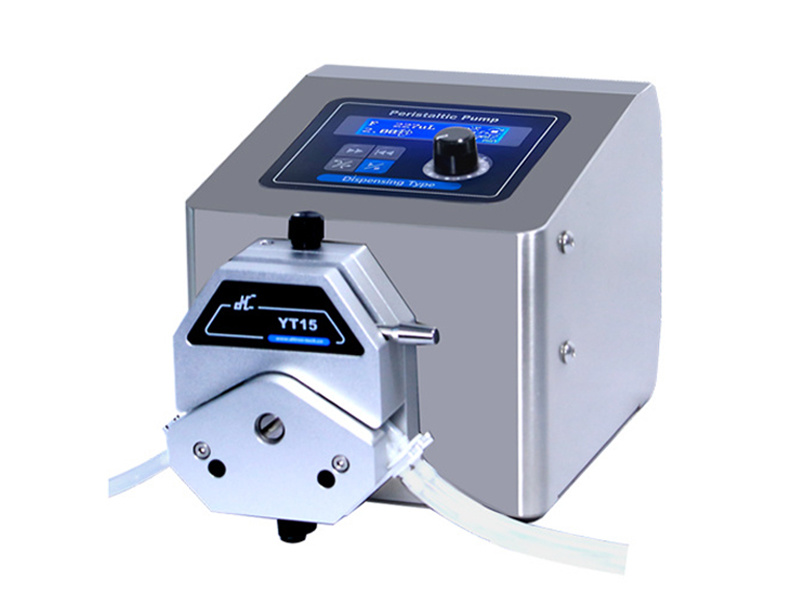

Thanks to its core advantages—non-contaminating conveyance, precise metering, and low shear force—peristaltic pumps have established a significant presence in the biopharmaceutical industry and are widely used throughout the entire process, from R&D pilot studies to large-scale production. Below are specific application scenarios, key advantages, and important considerations for pump selection:

I. Core Application Scenarios

- Cell Culture and Fermentation Processes

- Quantitative addition and replenishment of culture media and buffers: Avoid contamination, precisely control the rate of nutrient supply, and adapt to both batch fermentation and continuous fermentation modes.

- Fermentation broth sampling and supernatant transfer: The low-shear design protects cell viability and prevents cell rupture, thereby ensuring high product recovery rates.

- Inoculum Transfer: Achieve efficient inoculation in a sterile environment to reduce the risk of contamination by unwanted microorganisms.

- Purification and Separation Steps

- Sample loading and eluent delivery in chromatography columns: Precisely control flow rate and volume to ensure the stability and reproducibility of chromatographic separation performance.

- Feed for membrane filtration/ultrafiltration processes: A stable flow rate ensures consistent pressure on both sides of the membrane, thereby enhancing filtration efficiency.

- Buffer Preparation and Delivery: Meeting precise fluid requirements for processes such as pH adjustment and ionic strength optimization.

- Preparation and Filling Operations

- Quantitative dispensing of pharmaceutical solutions: High-precision filling suitable for small-dose injections and biological agents, reducing waste of pharmaceutical solutions.

- Lyophilization of drug solutions: Low-shear-force transfer protects the spatial structure of protein-based drugs, preventing loss of activity.

- Additives: Precise metering and mixing of additives such as preservatives and co-solvents.

- CIP/SIP Cleaning and Sterilization

- The pump tubing is capable of withstanding high-temperature sterilization and chemical cleaning, making it suitable for sterile production requirements when conveying cleaning solutions and sterilizing agents (such as sodium hydroxide solution, hydrogen peroxide, and steam-compatible fluids).

II. Core Advantages in the Biopharmaceutical Field

- Fluid is pollution-free.

The fluid comes into contact only with the pump tubing; the pump head contains no sealing elements, valves, or other components that are prone to contamination, thereby preventing impurities such as metal ions and lubricants from entering the pharmaceutical solution and ensuring compliance with GMP standards.

2. Low-shear force protection

Peristaltic pumps deliver fluids by means of rollers that squeeze a flexible tube, generating shear forces on the fluid that are significantly lower than those produced by centrifugal or diaphragm pumps. This effectively protects the activity of sensitive materials such as biomacromolecules (e.g., proteins, antibodies), cells, and vaccines.

3. Precise measurement and controllability

It supports both constant-volume and constant-speed modes, with a flow accuracy of up to ±1%. Moreover, it features a wide flow adjustment range, making it suitable for various process requirements—from microliters per minute to liters per minute.

4. Easy to clean and sterilize

- The pump tubing can be quickly replaced with no risk of cross-contamination.

- Food-grade and pharmaceutical-grade pump tubing (such as silicone tubing and fluororubber tubing) can withstand steam sterilization at 121℃, gamma-ray sterilization, or chemical sterilization, meeting the requirements for sterile production.

III. Key Considerations for Model Selection

- Pump pipe material compatibility

- Pump tubing that comes into contact with the pharmaceutical solution must comply with... USP Class VI 、 FDA Meets pharmaceutical-grade certification standards.

- Select according to the fluid’s chemical properties: Silicone tubing is suitable for aqueous buffers and culture media; fluororubber tubing resists organic solvents, strong acids, and strong bases; PTFE tubing is appropriate for highly corrosive fluids.

- Accuracy and Flow Range

- For R&D pilot testing, select a micro-peristaltic pump (in the μL range); for scaled-up production, choose an industrial-grade peristaltic pump (with high flow rate and high pressure).

- Prioritize those with Traffic calibration function The model ensures process repeatability.

IV. Precautions

- Regularly replace the pump tubing: Pump tubing will degrade over time due to prolonged compression, so it needs to be replaced periodically based on usage frequency to prevent fluid leakage or contamination caused by tubing rupture.

- Avoid operating under excessive pressure: Exceeding the pump tubing’s pressure rating can cause the tubing to rupture. It is essential to select an appropriate pump head and tubing that match the process pressure.

Keywords:

Previous

Next

Previous:

Next:

Product recommendation