Chemical Engineering

Published time:

2025-03-31

The core advantages of peristaltic pumps in the chemical and process industries are their excellent media compatibility, absence of cross-contamination, and precise, controllable flow rates. They can be adapted to a wide range of fluid-transfer applications—from small-scale laboratory trials to large-scale industrial production. They are particularly well-suited for handling corrosive, easily crystallizing, high-viscosity, or particulate-containing chemical media. Below are specific application scenarios, key advantages, and selection guidelines:

I. Core Application Scenarios

- Laboratory R&D and Pilot Testing

- Quantitative addition of reagents: For applications such as titration experiments, buffer preparation, and precise addition of catalysts, the flow rate accuracy can reach ±1%, meeting the requirements for experimental reproducibility.

- Reactor feed/sampling: The low-pulse delivery characteristic enables stable control of the reaction rate, preventing fluctuations in feed from affecting the reaction outcome. The sampling process leaves no residual medium, thus avoiding sample contamination.

- Supporting analytical instruments such as chromatographs and spectrometers: delivers mobile phases and standard solutions, suitable for micro-volume delivery requirements at the level of microliters per minute.

- Chemical production process

- Corrosive medium conveyance For strong acids (such as sulfuric acid and hydrochloric acid), strong bases (such as sodium hydroxide), and organic solvents (such as methanol and acetone), only the corrosion-resistant pump tubing needs to be replaced; the pump body itself is free from any risk of contact corrosion.

- High-viscosity / Particle-containing medium conveyance For materials such as coatings, inks, adhesives, and slurry-like substances, peristaltic pumps—being valve- and seal-free—do not suffer from clogging or wear issues. Their strong self-priming capability enables them to handle high-viscosity fluids.

- Auxiliary agent/additive metering and dosing For example, by adding defoamers, stabilizers, and pigments to the reaction system and precisely controlling their addition ratios, product consistency can be enhanced.

- Waste liquid treatment It conveys chemical wastewater containing solid particles, preventing pump blockage and reducing maintenance costs.

- Chemical Testing and Environmental Monitoring

- Online monitoring equipment suite: Continuously delivers water samples and reagents to the detection instruments, enabling real-time monitoring of chemicals in water quality and exhaust gases.

- Sample pretreatment: Such as transfer of extract solutions and delivery of digestion solutions, to avoid errors and safety risks caused by manual operations.

II. Core Strengths in the Field of Chemical Engineering and Chemistry

- Strong medium compatibility, no risk of pump body corrosion.

The fluid comes into contact only with the pump tubing; the pump head, motor, and other core components remain completely isolated from the medium. Simply select the appropriate pump tubing material—such as fluororubber or PTFE—based on the properties of the chemical medium to safely convey corrosive substances like strong acids, strong bases, and organic solvents.

- No cross-contamination, easy to clean and maintain.

- The pump tubing can be quickly removed and replaced, and dedicated tubing is used for different media to completely eliminate cross-contamination.

- No need to disassemble the pump body for cleaning—simply replace the pump tubing or clean the inner wall of the pump tubing, thereby reducing maintenance time and costs.

- Suitable for complex media and not easily clogged.

Keywords:

Previous

Next

Previous:

Next:

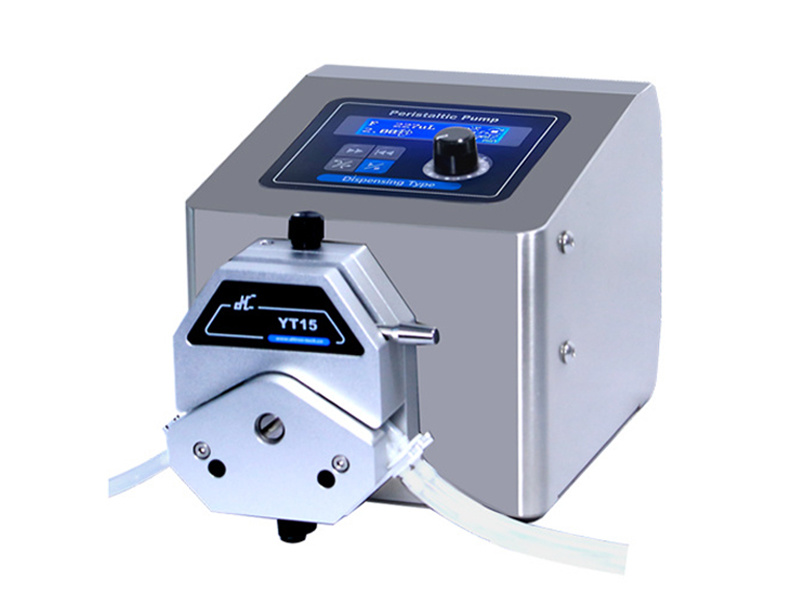

Product recommendation