Food and Beverage

Published time:

2025-03-31

The core advantages of peristaltic pumps in the food and beverage industry include food-grade compliance, zero cross-contamination, precise metering, and easy cleaning—making them suitable for the entire process from raw material handling to finished-product filling. They are particularly well-suited for conveying viscous materials, materials containing particles, or substances with high hygiene requirements. Below are specific application scenarios, key advantages, and selection guidelines:

I. Core Application Scenarios

- Raw Material Formulation and Delivery

- Conveying high-viscosity materials such as syrups, honey, and chocolate spreads. The peristaltic pump boasts strong self-priming capability and is equipped with no impeller, valve, or other components prone to clogging. It can reliably convey fruit jams and pulp slurries containing particles, effectively preventing blockages and material waste.

- Precise addition of additives Such as preservatives, colorants, flavorings, acidulants, and others, the flow rate accuracy can reach ±1%, enabling precise control of addition ratios and ensuring consistent taste and quality of the product.

- Ingredient mixing and conveying The water, sugar, milk powder, and other ingredients are conveyed to the mixing tank according to specified proportions, enabling automated ingredient preparation and reducing human error in manual operations.

- Filling and Dispensing Process

- Small-dose finished product filling For bottling or bagging of beverages, yogurt, fruit juices, and seasonings (such as soy sauce and vinegar), it supports fixed-volume mode, with precise and adjustable filling volumes, and is compatible with packaging of various specifications.

- Portioning of sauce products For the quantitative dispensing of viscous materials such as peanut butter, sesame paste, salad dressing, and the like, this solution addresses the issues of inaccurate filling and excessive residue inherent in traditional pump-based filling methods.

- Sample Collection and Testing Samples are taken from the production line for quality inspection, ensuring no residual media and preventing sample contamination.

- CIP In-Place Cleaning

The conveying and cleaning fluid—such as acid-alkali solutions or hot water—is used to clean the production line pipelines and tanks. The pump tubing is resistant to chemical cleaning and high-temperature sterilization. After cleaning, simply replacing the pump tubing allows for seamless material switching with no risk of cross-contamination.

4. Alcohol Brewing Process

- Transporting wort, fermentation broth, and alcohol-strength adjustment liquid;

- The wine body transfer in the filtration stage uses low shear force to avoid damaging the flavor compounds of the wine.

II. Core Competencies in the Food and Beverage Sector

- Food-grade compliance, safe and hygienic

Pump tubing that comes into contact with materials can be selected from: Food-grade silicone, fluororubber Material, compliant with FDA, EU 10/2011, GB 4806 Complies with food contact material safety standards, ensuring no harmful substances leach out and safeguarding food safety.

2. No cross-contamination, clean and convenient

- The fluid comes into contact only with the pump tubing; the pump head remains completely separate from the material. By simply replacing the pump tubing, you can switch between different materials, thereby completely eliminating cross-contamination.

- The pump tubing can be quickly disassembled, making it easy to clean and sterilize, and is well-suited to the hygiene requirements of the food industry.

Keywords:

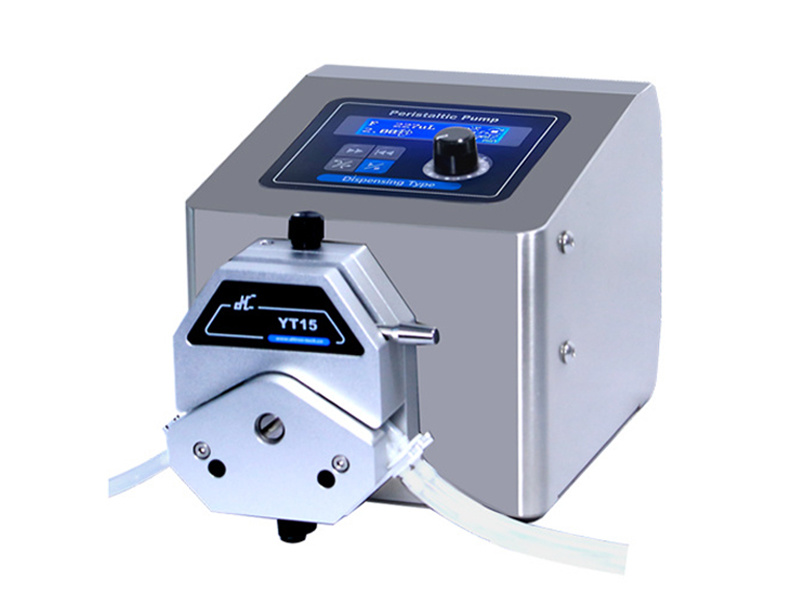

Product recommendation