GR1-6B

Category:

Tags:

- Product Description

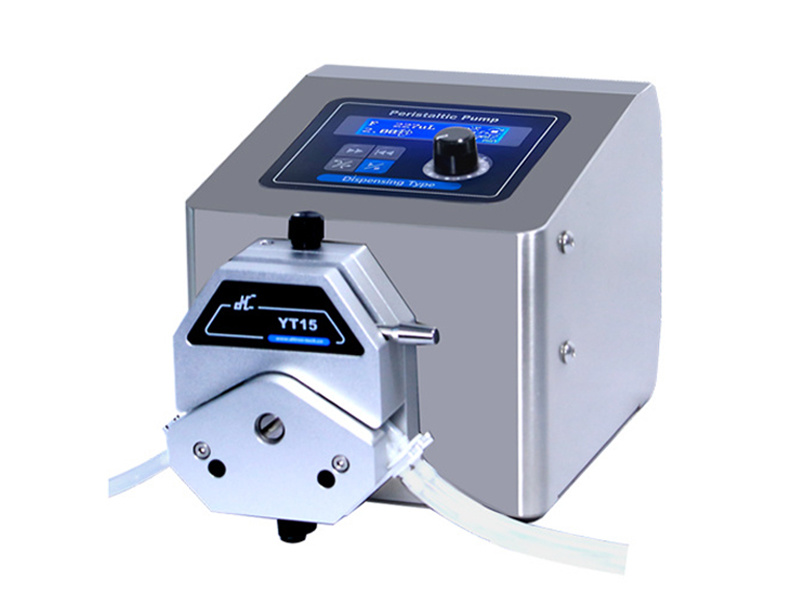

GR1-6B

-

- Commodity name: GR1-6B

Flow range: 0–500 ml/min; filling volume range: 0.1–8000 mL; optimal filling volume: 0.1–250 mL

Product Introduction

◆ Flow range: 0-500 ml/min

◆ Filling volume range: 0.1–8000 mL

◆ Optimal filling volume: 0.1–250 mL (Increasing the filling volume requires extending the filling time).

◆ Adopting DITRON-LED-DISPENSER-1 intelligent control technology, this product features an imported STM32 microcontroller for smart, timed, and quantitative dispensing. It delivers highly accurate liquid filling with a precision of up to ±1%.

◆ Utilizing a peristaltic pump for filling, driven by a stepper motor, this system features low vibration and high precision. The liquid flows solely through tubing, ensuring no contact with the pump body, thereby minimizing the risk of secondary liquid contamination to the greatest extent.

◆ The pump tubing is made from imported, long-life Saint-Gobain Pharmed hoses, which feature exceptionally long service life and outstanding corrosion resistance.

◆ Can be used to fill beverages, alcoholic drinks, petroleum products, daily chemical products, edible oils, soy milk, pharmaceutical solutions, pesticides, and other liquids—including those with certain viscosity or containing impurities.

◆ Preparation for medium aliquoting, as well as the aliquoting of other chemical reagents, can be carried out.

◆ Imported potentiometers regulate the flow rate.

◆ Filling operation time setting, interval time setting, filling cycle count accumulation, and presetting

◆ Three working modes are available: manual filling, automatic filling, and preset filling.

◆ Foot Pedal Switch Control

◆ 304 Stainless Steel Filling Nozzle

◆ Wide-range power supply, AC 90-260V, 50Hz/60Hz

Technical Specifications

Product Model GR1-6B Peristaltic pump tubing Standard equipment includes a 17# imported long-life Pharmed peristaltic pump tube (with imported food-grade silicone tubing for connecting pipelines). Filling Volume Setting Range 0.1–8000 mL Optimal Filling Liquid Volume 0.1-250mL Traffic Range 0-500mL/min Traffic Regulation Imported potentiometers regulate the flow rate (determining the size of liquid discharge from the filling nozzle). Number of Filling Nozzles Single-head Filling Mode Three working modes are available: manual filling, automatic filling, and preset filling. Display Function 4-digit LED display for filling operation time, 4-digit LED display for filling interval time, and 5-digit LED display for filling count. Filling Time Setting Set range: 0.01 seconds to 999.9 seconds Interval Time Setting Set range: 0.01 seconds to 999.9 seconds Number of fillings Displayed 59,999 times Filling Cycle Setting Two modes are available: cumulative count and preset count. Method of Operation Membrane button control offers convenience, speed, and reliability; imported potentiometer knobs allow for precise flow adjustment. Power-off Memory Function After power is restored, the parameters will remain in their pre-power-off state. Pressing the start button (or activating the foot switch) will resume operation using the previously set parameters. Foot Pedal Switch Control Standard foot pedal switch controls start and stop. Filling Bracket Standard filling bracket equipped, adjustable in height and length directions. Filling nozzle 304 Stainless Steel Nozzle Power Consumption <40W Applicable Power Supply Wide-range voltage AC 90-260V, 50Hz/60Hz Work environment 0-40°C, with humidity below 80% to prevent condensation. Dimensions 250mm x 180mm x 140mm (excluding the filling bracket) Weight 3.5KG Protection Level IP31 Selection Guide

Target Filling Volume (ml)

Filling Time (seconds)

Actual Filling Volume (ml)

Actual Filling Volume (ml)

Actual Filling Volume (ml)

Actual Filling Volume (ml)

Actual Filling Volume (ml)

5ml

0.7

4.99

4.90

4.96

4.90

4.90

10ml

1.4

10.16

10.01

10.04

10.33

9.99

20ml

2.87

19.99

19.86

19.93

20.11

19.86

50ml

7.10

50.05

50.34

50.13

50.27

50.06

100ml

15

99.86

99.68

99.56

100.15

99.90

◆ Note: Measurements were taken when the speed control knob was turned to its highest setting. Each filling volume was tested five times.

The experimental medium is water. This value is measured empirically and may vary between product batches. Additionally, changes in the medium can also affect the filling data.

As the medium viscosity increases, the filling machine flow rate decreases, resulting in longer filling times.

Dimensions

Related products

Get a free product quote

Fill in your phone and E-mail information, and we will contact you within one working day to solve your problems as soon as possible.