Belt-driven peristaltic pump filling machine

Category:

Tags:

- Product Description

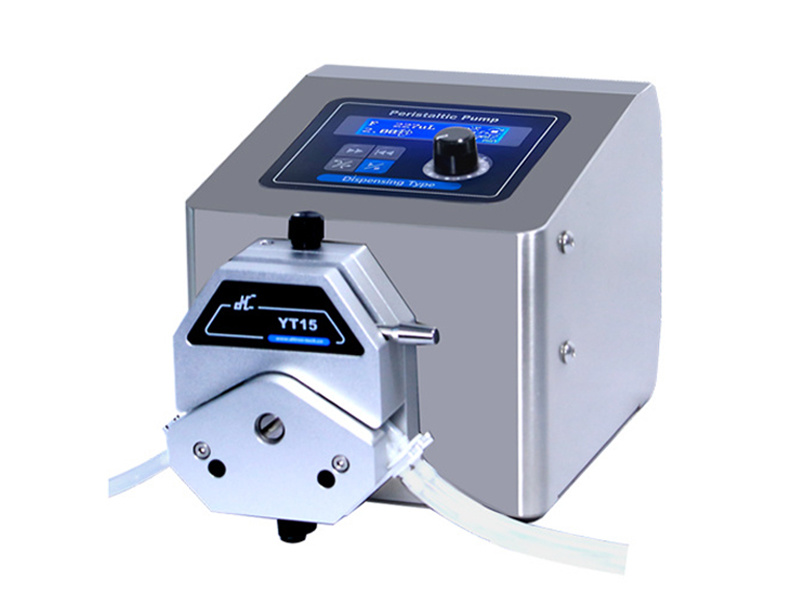

Belt-driven peristaltic pump filling machine

-

- Commodity name: Belt-driven peristaltic pump filling machine

Belt-driven peristaltic pump filling machine: Ideal for high-precision liquid transfer ranging from 0.02 to 6000 mL/min, as well as precise liquid filling operations between 0.05 and 500 mL.

DG-A DG-B Pump head

DMD15 Pump head

313D Pump head

KZ25 Pump head

Product Introduction

◆ Suitable for high-precision liquid transfer ranging from 0.02 to 6000 mL/min, as well as liquid filling operations between 0.05 and 500 mL.

◆ Industrial touch screens operate synchronously with membrane buttons, offering simplicity, convenience, and speed.

◆ Adaptable to a variety of pump heads to meet diverse needs, including YZ15(25), DG series, DMD15, 313D, KZ25, and other models.

◆ The filling machine is linked with the conveyor belt, and fiber optics detect the position of the bottles.

◆ The conveyor belt speed is adjustable, and the cumulative count of filled bottles can be reset to zero.

Control Panel

◆ Input parameters such as filling liquid volume, running time, interval time, and number of runs, among others.

◆ Suitable for high-precision liquid filling.

◆ Cumulative total liquid volume and cumulative total operating time functions;

◆ Liquid volume calibration function: Input the measured liquid volume value to complete the liquid volume calibration.

◆ Scheme Storage and Retrieval Function

Technical Specifications

Drive Model CF600B CF600S Applicable Pump Head YZ15, YZ25, 313D, DMD15, YT15, YT25 KZ25, KT25 Traffic Range 0.013-3200mL/min 0.09-6000mL/min Rotational Speed Range 0.2-600rpm 0.2–600 Applicable Filling Range 0.1mL-200mL 10-500mL Cumulative Liquid Volume Total Liquid Volume Accumulation and Zeroing Function Time Accumulation Cumulative and Reset Function for Total Runtime Scheme Storage Save the current running scheme for easy recall. Liquid Volume Calibration Input the measured filling volume for automatic calibration, achieving higher-precision liquid transfer and filling. Suction Speed Setting Set the back-suction speed to prevent dripping after shutdown, with a speed range of 10–300 rpm. Backflow Angle Setting Set the backflow angle to prevent dripping after shutdown. The angle range is 10–720°, and it can also be set to 0°. Screen Lock Feature Screen lock to prevent accidental touches or unauthorized parameter changes. Full-speed Function Rapid Filling and Emptying Hose for Liquids Direction Control Control of Liquid Transfer Direction Appointment Initiation Set the date and time to schedule the startup. Scheduled Startup Initiate automatically at the scheduled time. Language Settings Switch between Chinese and English interfaces Factory Reset Factory Reset Function Rotational Speed Control Accuracy Error ≤0.2% Start-Stop Control External signal start/stop control, with options for switch-level and voltage-based methods. Foot Pedal Switch Optional foot switch control for start and stop Communication Function Adopt the Modbus RTU communication protocol Filling Time 0.1s-9999.9Hr Interval Duration 0.1s-9999.9Hr Method of Operation 4.3-inch Industrial Touch Screen with Membrane Keypad Number of Assignments 0-99,999 times (0 indicates infinite loop) Work Environment Temperature: 0–40°C, Relative Humidity < 80% Applicable Power Supply AC 90–260 V, 50/60 Hz Drive Size 220x162x206mm Conveyor Belt Dimensions 1000mm Protection Level IP31 External Signal Control

◆ Start/stop control: The start/stop control port is connected to the conveyor belt's start/stop port. Once the fiber optic sensor detects a bottle, automatic filling is initiated.

Selection Guide

Drive Pump head Number of rollers Number of channels Hose Model Rotational Speed Range Flow Range (ml/min) CF600B YZ15 3 1,2 13# 0.2–600 0.016–46.1 #14 0.054-178.1 19# 0.104-336.9 #16 0.172-556.2 #25 0.36-1176.6 #17 0.64-2111.6 #18 0.128-2400 YZ25 1,2 #15 0.34-1066 #24 0.58-1856 #35 0.74-2370 313D 3 1 13# 0.016–46.1 #14 0.054-178.1 19# 0.104-336.9 #16 0.172-556.2 #25 0.36-1176.6 #17 0.64-2111.6 #18 0.128-2400 DMD15 3 1 2*13# 0.026 - 47.07 2*14# 0.098 - 266.45 2*19# 0.19-564 2*16# 0.32-941 2 × 25# 0.68-1371 2*17# 1.1-3200 CF600S KZ25

KT25

3 1,2 #15 0.2–600 0.59-1800 #24 0.95–3200 #35 1.4 - 4500 #36 1.9 - 6000 Dimensions

Product Video

Related products

Get a free product quote

Fill in your phone and E-mail information, and we will contact you within one working day to solve your problems as soon as possible.