GR4-1BD+YZ15 Intelligent Peristaltic Pump Filling System

Category:

Tags:

- Product Description

GR4-1BD+YZ15 Intelligent Peristaltic Pump Filling System

-

- Commodity name: GR4-1BD+YZ15 Intelligent Peristaltic Pump Filling System

Four-channel Filling System: Designed for liquid filling applications ranging from 0.1 to 100 ml, equipped with a convenient 7-inch industrial touch screen for easy operation, and compatible with YZ series pump heads.

GR4-1BD Peristaltic Pump Intelligent Filling System

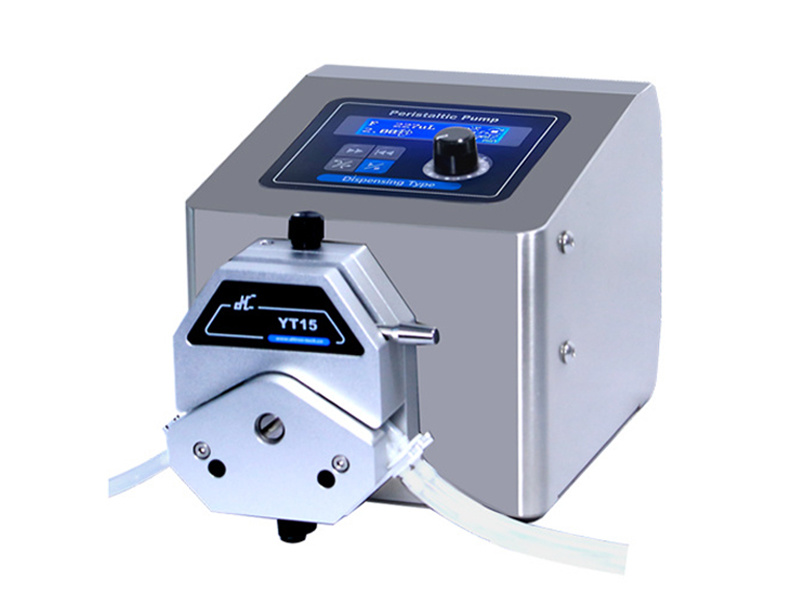

YZ15 DMD15 Product Introduction

◆ Adopting peristaltic pump filling, the liquid flows only through the tubing, ensuring no cross-contamination.

◆ Suitable for filling liquids ranging from 0.1 to 100 ml.

◆ The drive unit is designed as a standalone module for easy integration with customer systems. The 7-inch industrial touch screen ensures convenient operation, while the menu-based interface offers a clear and user-friendly experience.

◆ Multiple pump heads are available, including the YZ15, YZ25, and DMD15 models. When using the YZ series pump head, the filling accuracy is ±2%. With the optional DMD15 pump head, the filling accuracy can be as high as ±1%.

◆ The 4-channel configuration serves as the basic structure and can be assembled in a modular fashion. By stacking and installing, it can be expanded up to a maximum of 32 channels.

◆ Each channel address can be conveniently adjusted via its dedicated mask button and clearly indicated by an LED.

◆ It features three operational modes: internal control, external control, and communication control, catering to the needs of different users.

◆ Each channel is equipped with an independent function to stop filling upon bottle shortage.

◆ The external communication interface uses an RS485 bus, with adjustable baud rates and parity settings. The communication protocol is based on the standard Modbus protocol.

◆ Control the start/stop and left/right turning of each channel of the execution unit as desired.

◆ Capable of controlling single-channel or multi-channel operations for simultaneous draining and recovery.

◆ The suction angle and suction duration can be set, and all channels perform suction simultaneously.

◆ Provides password functionality: Protects system parameters set by users to prevent accidental operations.

◆ Provides functions for saving and recalling filling schemes.

◆ Provides multiple calibration functions: ratio adjustment, volume calibration, and weighing calibration, with independent calibration for each channel.

◆ Provides an online adjustment function, allowing users to conveniently modify the liquid output settings online.

Typical Applications

◆ Pharmaceutical Plant: Liquid Filling Process

◆ Pharmaceutical Machinery Accessories

◆ Vaccine Filling

◆ Reagent Filling

Control Panel

External Signal Control

◆ Each channel is equipped with an independent function to stop filling upon bottle shortage.

◆ External switch signals control the start and stop of each channel.

Technical Specifications

◆ The filling system execution unit can be equipped with various pump heads and corresponding hoses. Quantitative filling is performed via the filling system controller.

◆ The following table provides all applicable pump heads and hoses for the filling system, along with the recommended filling ranges in seconds:

Pump Head Model Applicable Hose Filling range (ml) when filling time is 1 second Silicone tube Pharmed Management YZ15 13# 13# 0.1 ml - 0.5 ml #14 #14 0.2 ml - 2.3 ml 19# 19# 0.5 ml - 5.1 ml #16 #16 1.0 ml -9.1 ml #25 #25 2.0 ml - 19 ml #17 #17 3.0 ml - 30 ml YZ25 #15 One 1.0 ml - 17 ml #24 One 1.5 ml - 24 ml DMD15 2*13# 2*13# 0.1 ml - 0.9 ml 2*14# 2*14# 0.3 ml - 3.0 ml 2*19# 2*19# 0.5 ml - 5.9 ml 2*16# 2*16# 1.0 ml - 10.2 ml 2 × 25# One 2.0 ml - 20 ml 2*17# One 5.0ml-50ml Dimensions

Related products

Get a free product quote

Fill in your phone and E-mail information, and we will contact you within one working day to solve your problems as soon as possible.