GR6-6BS Peristaltic Pump Filling System

Category:

Tags:

- Product Description

GR6-6BS Peristaltic Pump Filling System

-

- Commodity name: GR6-6BS Peristaltic Pump Filling System

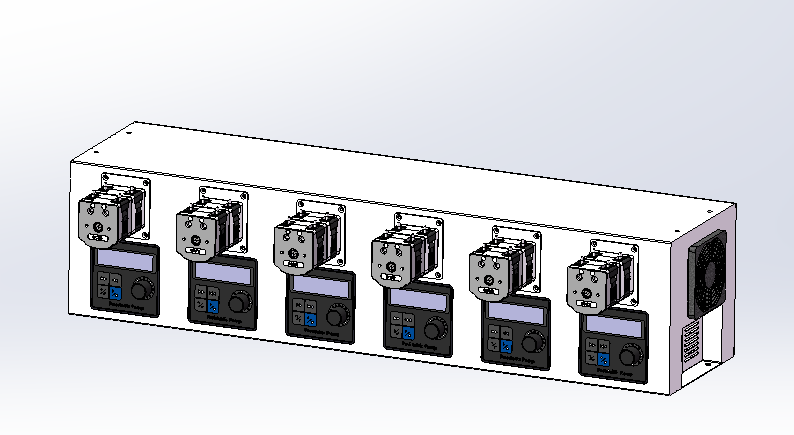

Divided into 6 independent execution units, each controlled by a dedicated control panel. It is ideal for filling liquids ranging from 50 µL to 700 µL, with filling accuracy maintained within approximately ±1%. The housing is made of 304 stainless steel, while the pump heads are model KZ15-18. These dual pump heads are installed using a phase-compensation mechanism and fixed in a precise 4-layer stacked configuration, creating a total of 24 filling channels.

GR6-6BS Peristaltic Pump Technical Specifications

Product Introduction

◆ The GR6-6BS peristaltic pump is divided into 6 execution units, each controlled by a separate control panel.

◆ Suitable for filling liquids ranging from 50 µl to 700 µl, with filling accuracy maintained within approximately ±1%.

◆ The exterior is made of 304 stainless steel.

◆ The pump head is KZ15-18, with a phase-compensation installation method for the two pump heads.

◆ 4-layer stacked installation and fixation, forming 24 channels

◆ Switching contact control, with 24 channels enabled and disabled simultaneously.

Applicable Pump Head

Pump head series connection

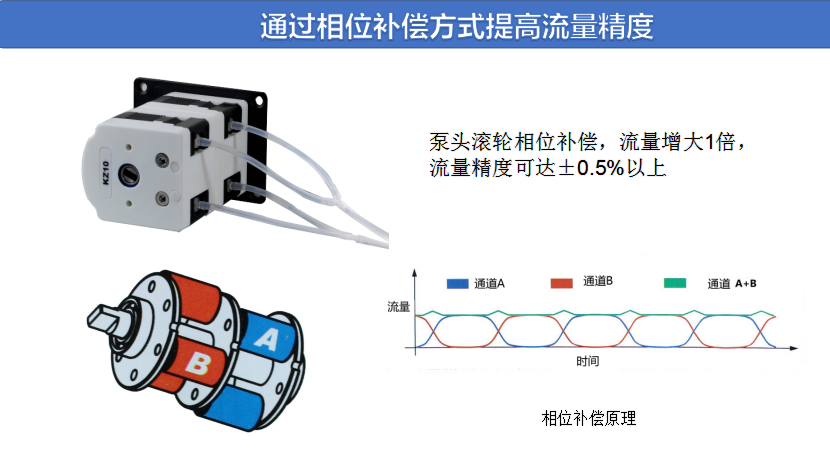

◆ Two pump heads are connected in series, with the front and rear pump head rollers installed offset from each other—specifically, the front pump head roller is positioned between the two rollers of the rear pump head.

◆ The inlet and outlet pipelines of the front and rear pump heads are connected separately using three-way fittings, allowing the fluids in the front and rear pump head pipelines to mutually compensate for each other.

◆ Liquid pulsation is significantly reduced, with flow accuracy exceeding ±0.5%.

Technical Specifications

Product Model GR6-6BS Rotational Speed Adjustment Range 1-300RPM Rotational Speed Resolution 1RPM Portioning Function Quantitatively dispensing liquids Filling accuracy error Around ±1% Number of Repackaging Times 1 to 9,999 times ("0" indicates infinite looping) Dispensing Time Interval 0.1S-24Hr Display function 128×32 graphic dot-matrix LCD display, showing flow rate and rotational speed on the same screen Direction Control Reversible Operation Direction Function Operating Method The rotary encoder switch, combined with the membrane keypad operation, offers users greater convenience. Full-speed function The pipeline can be quickly filled and drained using the full-speed button. Power-loss memory function After power is restored, resume operation according to the state before the power outage. Retraction function Operating in distribution mode, the pump reverses direction by a certain angle after shutting down, effectively preventing liquid from dripping. Liquid Volume Distribution Correction Function Enter the actual liquid allocation value to automatically perform liquid allocation correction. Start-stop control Switching contact control for start/stop Dispensing Bracket Optional filling bracket installs the filling nozzle. Power Consumption <150W Applicable Power Source AC 200–260V, 50Hz/60Hz Work environment 0–40°C, humidity <80% with no condensation Protection Level IP31 External dimensions

◆ The six M6 threaded holes at the bottom are for mounting.

Related products

Get a free product quote

Fill in your phone and E-mail information, and we will contact you within one working day to solve your problems as soon as possible.