I-Input to Left

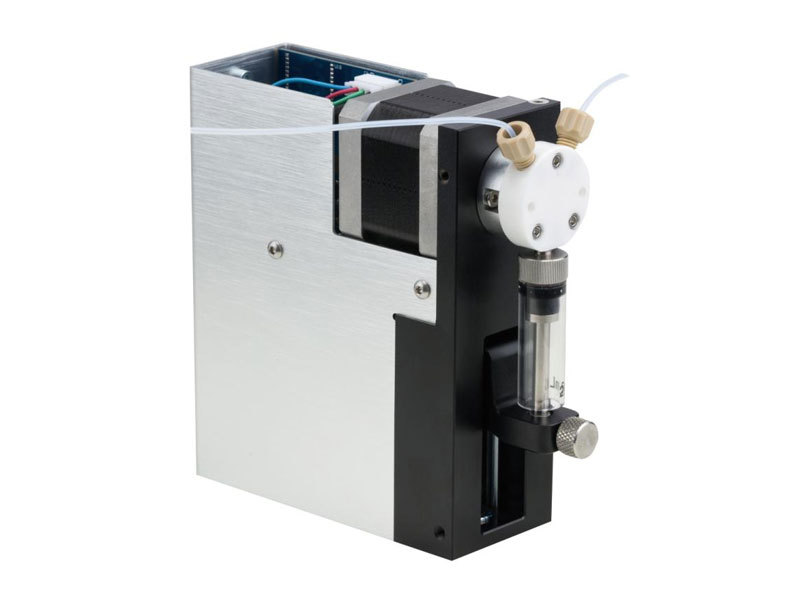

MSP30 Industrial Syringe Pump

Category:

Tags:

- Product Description

MSP30 Industrial Syringe Pump

-

- Commodity name: MSP30 Industrial Syringe Pump

Primarily used in equipment and instruments, especially for the process automation of programmed tasks

Product Introduction

◆ The MSP30 is a compact OEM product for precise fluid transfer. It is controlled by a computer or microprocessor to automatically perform liquid handling, dilution, and dispensing functions.

◆ Rated stroke 30mm

◆ Stepper motor drive, precision lead screw transmission, mechanical reversing, with high transmission stability

◆ Can accommodate 50μl, 100μl, 250μl, 500μl, 1ml, 2.5ml, 5ml glass syringes

◆ The valve body and fluid path materials have excellent chemical properties and are suitable for various neutral and corrosive solutions;

◆ Controlled by external signals or PC communication

Typical Applications

◆ Mainly used in equipment and instruments, especially for process automation of programmed tasks

Technical Parameters

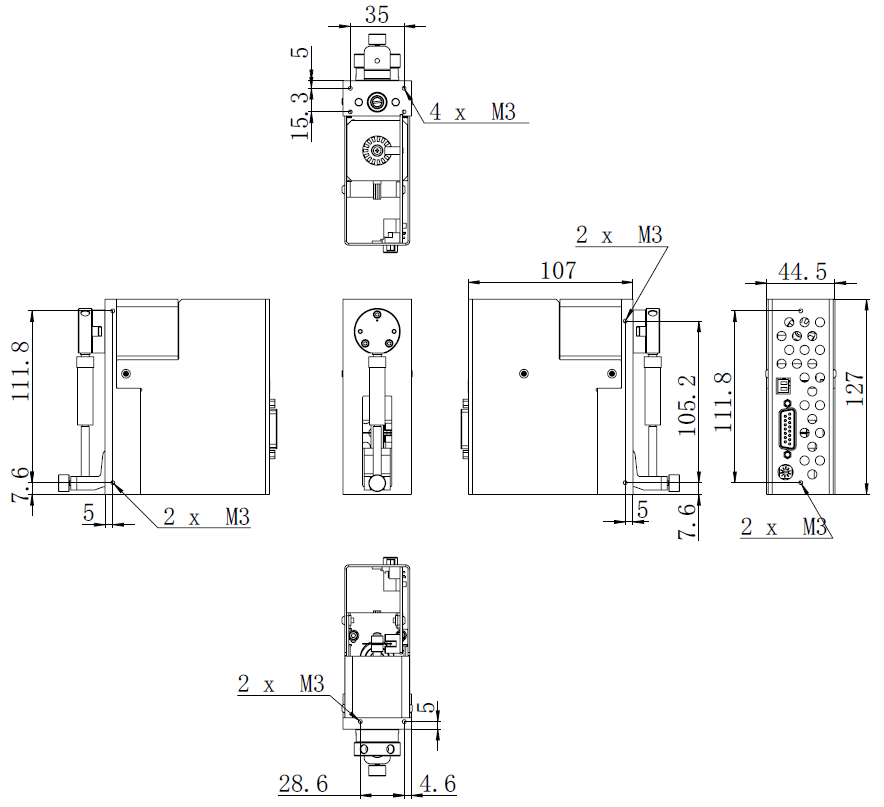

Applicable Syringes 50μl, 100μl, 250μl, 500μl, 1ml, 2.5ml, 5ml Liquid Volume Accuracy Error ≤ ±1% (rated stroke) Repeatability Precision Repeatability error ≤ ±0.5% (rated stroke) Linear Velocity Range 0.025mm/s-25mm/s Fluid Path Material Ceramic, borosilicate glass, PTFE, CTFE Dimensions (L*W*H) 110*44.4*127 (mm) Weight 0.8Kg Applicable Power Supply DC24V/1.5A Fluid Path Interface 1/4-28 internal thread interface Syringe Material Silicate glass, PTFE-coated stainless steel plunger Control Steps and Resolution (Standard Mode) Full stroke 3000 steps, control resolution 0.01mm/step Control Steps and Resolution (Microstep Mode) Full stroke 48000 steps, control resolution 0.625um/step Rated Stroke Running Time 1.2s-1200s Valve Type 3-port 120° ceramic valve, supports PCTFE material 3-port 120° Valve Switching Time (Between Adjacent Ports) <280ms Fluid Path Pressure Reference Value ≤0.68Mpa Communication Interface RS485/USB dual communication interface, auto-identification Communication Rate 9600bps/38400bps configurable via communication commands Communication Address Setting 4-bit BCD DIP switch setting for 15 communication addresses Signal Input 2-channel TTL level signal input, used to control restart after pause command Signal Output 3-channel TTL level signal output, used to indicate operating status Operating Ambient Temperature 15℃-40℃ Operating Ambient Relative Humidity <80% Z Initialization Command

Y-Initialization Command

Valve Application Example (Three-Port Valve)

Selection Guide

Syringe Size

Minimum Flow Rate

Maximum Flow Rate

50uL

0.0025 mL/min

2.5 mL/min

100uL

0.0050 mL/min

5 mL/min

250uL

0.0125 mL/min

12.5 mL/min

500uL

0.025 mL/min

25 mL/min

1mL

0.050 mL/min

50 mL/min

2.5mL

0.125 mL/min

125 mL/min

5mL

0.25 mL/min

250 mL/min

Dimensions

Related products

Get a free product quote

Fill in your phone and E-mail information, and we will contact you within one working day to solve your problems as soon as possible.